If your business or community has food waste, and you don’t want it ending up in a landfill, you’ll need to turn to a commercial solution (in scale, if not an actual third party) to deal with it. Most of these solutions will fall into the use of bacteria to break down this organic material into reusable products – with two major types with one distinction. Breaking this down in a controlled, open-air process (aerobic) simply referred to as composting or breaking it down in a sealed structure (anaerobic). Let’s look at anaerobic digestion vs. composting to see which both bring at the commercial scale.

Understanding Commercial Composting

Of the two options, composting is both much more easily recognizable and has less complexity, not dissimilar to what you might see in a residential community, but on a much larger scale when commercialized. Here are roughly the steps that are taken:

- Food waste is collected and taken to the processing facility. A simple sort is done to pull out any large pieces of contaminates.

- Some of the food waste is mixed with nitrogen-rich materials (often animal manure) into a slurry.

- This slurry is mixed with carbon-rich materials, usually food waste, yard debris, and paper products in a composting ratio.

- The product is laid out in long rows and turned and watered regularly to promote decomposition.

The end product – compost – can then be resold to commercial farmers, stores, or local residents for agricultural or gardening purposes.

Understanding Anaerobic Digestion Facilities

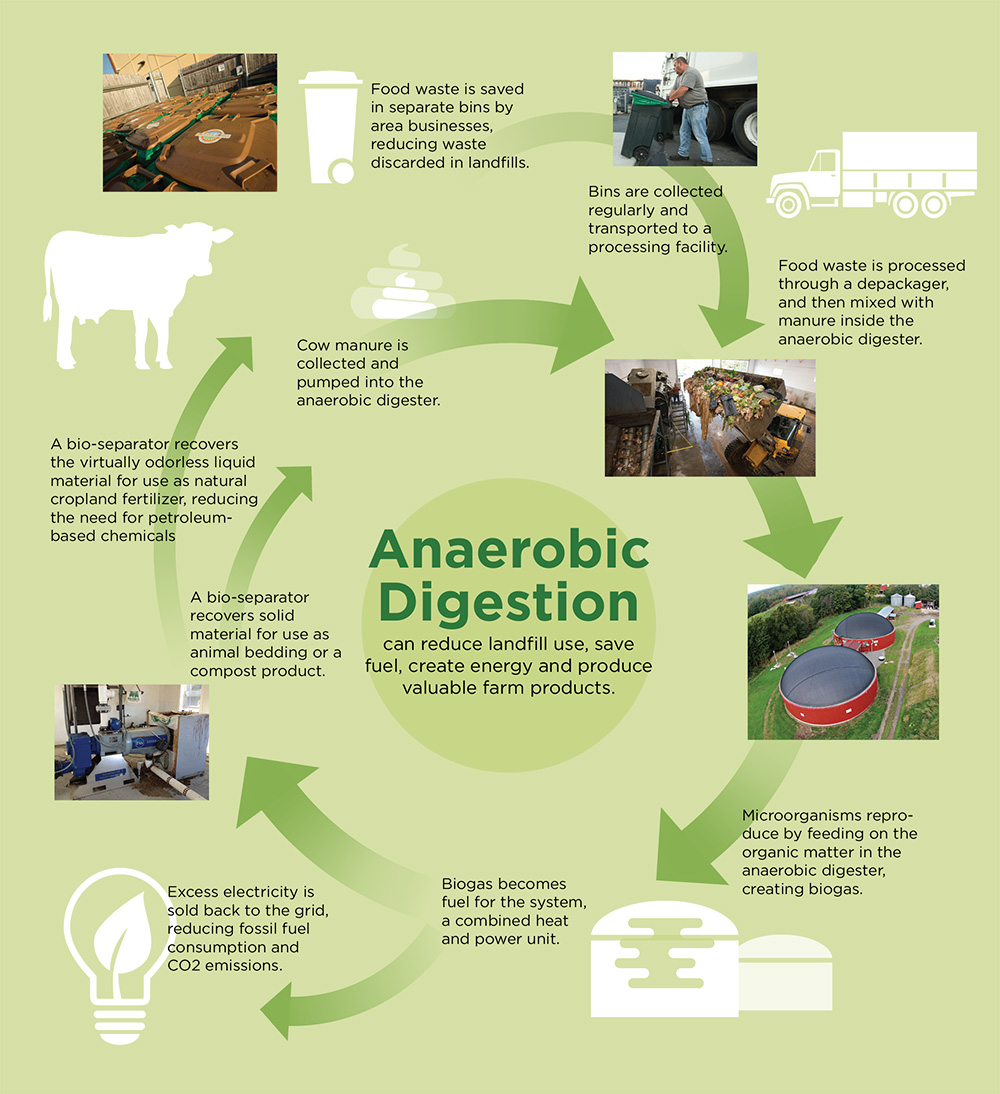

In many ways, anaerobic digestion (or AD) is the same concept with an eye to retaining more of the products from decomposition. By performing a similar process (combining food waste with nitrogen, carbon-rich materials, and water) but in an enclosed structure, it can capture waste products like biogas, decomposition liquids, and even waste heat for further use. An example of the AD process is below, using Agri-Cycle as an example:

As you can see, the capture of these additional products can then be recycled or repurposed, especially in our case where our AD partner, Exeter Agri-Energy, is located alongside our parent company, Stonyvale Farm – a ready source of nitrogen-rich manure and recipient of some of our bi-products like animal bedding. Other materials are even used in composting!

Comparing AD and Composting in Terms of Sustainability

As you might have gathered from the above two sections, while the process is actually very similar – collecting food waste, adding nitrogen, and using bacteria to break it down into reusable products, the AD’s capture of a lot of waste products makes it more sustainable – but that comes with a cost. These facilities require a lot of specialized equipment to capture and use that biogas, as well as to extract the other materials such as liquids and other solid materials, and therefore there are few AD facilities in the US.

Which is right for you? While our processing partners and commitment to sustainability put us in camp AD, we will be the first to point out that any reduction in food loss and waste is the right move. If you have commercial agricultural needs, you might need compost over the liquid fertilizers products by AD. Maybe you’re looking to handle food waste yourself and want to go with a simple solution. Or composting might be the only option available in your area. But here at Agri-Cycle, we will always recommend anaerobic digestion for a better closed loop.

And luckily for you, we’ve got a very large service area! From Maine to Maryland, we’ve got extensive coverage for all our services, from solid and liquid food waste to processing packaged goods, we can help. If you’re interested in learning more about what we do or how we can put anaerobic digestion to work for your business, contact us today.